In today’s demanding industrial landscape, the components that often receive the least attention can be the most critical to operational success. At Precision Products UK, we’ve witnessed firsthand how properly engineered sealing rings serve as the unsung heroes in high-temperature applications across marine, locomotive, and industrial sectors.

Why Sealing Rings Matter in Extreme Conditions

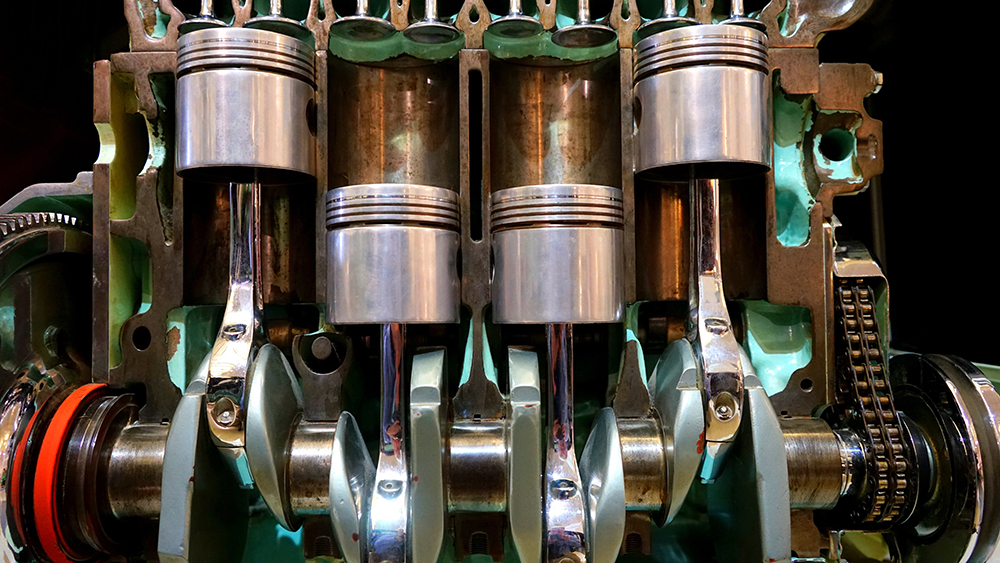

When operating environments reach temperatures that would compromise standard components, specially designed sealing rings become essential. These precision-engineered components create reliable barriers between moving parts, preventing leakage and maintaining system integrity even under the most challenging conditions.

The Physics of High-Temperature Sealing

The challenge with high-temperature environments lies in material properties. As temperatures rise, most materials expand, potentially creating gaps in sealing systems. Our sealing rings are designed with precise expansion coefficients that account for these thermal changes, ensuring consistent performance regardless of temperature fluctuations.

In engines and industrial machinery operating at elevated temperatures, the risk of system failure increases dramatically without proper sealing solutions. This is particularly true in marine applications, where reliability isn’t just about efficiency—it’s about safety.

Advanced Materials in Modern Sealing Rings

The evolution of sealing technology has been remarkable. At Precision Products UK, our research and development laboratory in Chesterfield utilises state-of-the-art equipment to test and develop innovative sealing solutions.

The Revolution of Metallic Seal Coatings

Metallic seal coatings represent one of the most significant advancements in our industry. These specialised coatings enhance durability, reduce friction, and improve heat resistance—critical factors in extending the operational life of piston rings and other sealing components.

Our UK-based coating facilities allow us to apply precise metallic seal coatings that dramatically improve performance metrics. These coatings can increase service intervals by up to 40% in certain applications, delivering substantial operational cost savings for our clients.

Selecting the Right Sealing Solution for Your Application

When it comes to high-temperature environments, one size definitely doesn’t fit all. The requirements for a marine diesel engine differ significantly from those of stationary industrial machinery.

Customisation and Precision Engineering

At Precision Products UK, we approach each project individually, analysing the specific operational parameters before recommending or designing a sealing solution. Our comprehensive range of piston rings and metallic seals serves medium to large bore engines across various industries.

What sets us apart as piston ring suppliers is our attention to detail. Each sealing ring is manufactured to exacting tolerances, ensuring optimal performance even in the most demanding conditions. This precision engineering is why major industry players continue to trust our solutions.

The Future of Sealing Technology

As industrial processes continue to push temperature and pressure boundaries, sealing technology must evolve accordingly. Our ongoing research focuses on developing new alloys and coating technologies that extend operational capabilities even further.

The industrial landscape is changing rapidly, but one constant remains: the need for reliable sealing solutions in high-temperature applications. As specialists in this field for decades, we at Precision Products UK continue to lead innovation in sealing technology.

For more information about our extensive range of sealing solutions or to discuss your specific requirements, visit our website at Precision Products UK or contact our technical team directly. With our extensive stock and distribution capabilities, we’re equipped to provide timely solutions for even the most urgent sealing requirements.