Marine Applications

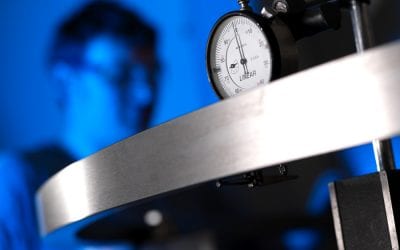

Advancements in Marine Piston Ring Technology

In the ever-evolving maritime industry, piston ring technology continues to play a crucial role in enhancing engine performance and reliability. As a leading British manufacturer, Precision Products UK (PPUK) remains at the forefront of these technological...

How Future Fuels for Marine Engines Are Reducing Emissions and Protecting the Environment

Maritime shipping is indispensable to world trade, transporting around 80% of goods. As a result, it also accounts for an estimated 3% of worldwide greenhouse gas emissions. As climate change continues to cause worldwide supply chain disruption, could switching to...

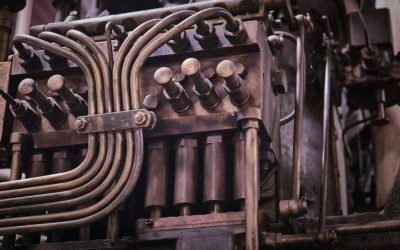

A Guide To Marine Engines

Marine engines are the heart and soul of any watercraft — from small recreational boats to massive cargo ships. These powerful machines are designed to withstand the harsh conditions of the open sea while providing reliable and efficient propulsion. Understanding the...

How to find the right piston rings for your boat

If you're looking for marine piston rings, you may be overwhelmed at the number of piston ring suppliers and be unsure which manufacturer you can trust. Below we outline 4 effective ways to identify a high-quality, dependable piston ring manufacturer. 1. Research and...

How to remove carbon build-up from your boat engine

After a long period of time, black carbon soot can build up on the piston rings, cylinder head, valves, and cylinder wall of your engine as a by-product of combustion. This can impact the overall performance of your engine by leading to engine knocking, increased oil...

3 Common Misconceptions About Marine Piston Rings

Piston rings have many uses. Primarily they are used to seal combustion chambers in marine diesel engines. If you are searching for a piston ring manufacturer, you will most likely be overwhelmed with information about marine piston rings, some of which is inaccurate....

Industrial Applications

How Do We Meet the Demands of Locomotive Engines at PPUK?

At Precision Products (PPUK), we understand the complex and evolving needs of the locomotive industry. Our commitment to excellence in manufacturing piston rings and sealing rings places us at the forefront of the engineering sector. With decades of experience and a...

Keeping the Flying Scotsman on Track for a Spectacular Centenary

Helping to make Heritage Railway History The Flying Scotsman is 100 years old in late February 2023. To mark the occasion, there is a huge program of events planned. These include: An Exhibition of illustrations of this great piece of railway heritage A dedicated...

Benefits of UK Made Piston Rings and Metallic Seals

When you are buying a product such as piston rings or metallic seals, you may think that the parts you buy from overseas are the same as those you buy from the UK. However, there can be major benefits to buying UK manufactured parts such as hydraulic rings or rings...

Piston Ring Fundamentals

How Piston Rings Impact On Fuel Efficiency

You may already be aware that piston rings play a crucial role in transferring heat to prevent an engine from overheating. But did you know they can also improve an engine’s fuel efficiency? Locomotive and marine engines are designed to operate under heavy loads for...

The Impact Of IMO2020 On Piston Rings

IMO fuel regulations have been in place since 1 January 2020. Yet only now is the full impact of the 0.5% sulphur cap coming to light. In this article, we’ll take a closer look at the effects of low sulphur fuels on piston rings and what that could mean for your...

Why are there so many different types of joints used on piston rings?

Why are there so many different types of joints used on piston rings? Have you ever wondered why there are so many different types of joints used in piston ring design? The first in our series of “Frequently Asked Questions” videos, will help you to understand the...

What are piston rings made of?

Piston rings operate at higher temperatures than fabric, elastomeric, or polymer seals. If damaged, sealing rings allow engine oil to become polluted by hot exhaust leaking from the cylinder into the crankcase. So what are piston rings made of and how do these...

How to fit piston rings

If you’re not sure how to fit industrial piston rings, we’ll cover everything you need to know in this short five-step guide. If you still have questions at the end, our technical experts will be on hand to help. 1. Fit with caution & use the right equipment...

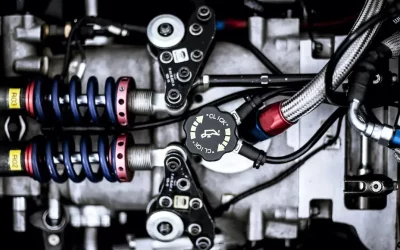

The Importance of Flexibility in Piston Ring Manufacture

Stop a person in the street and ask them to explain what a piston ring does – they’ll probably struggle to give you an answer. These days, many people take for granted the intricate combustion engines that drive the trains that ferry them to and from work, the cargo...

Piston Ring Materials & Coatings

Understanding Ceramic Chrome Piston Rings: Benefits and Applications

Introduction Piston rings play a crucial role in engine performance, ensuring efficient sealing between the piston and cylinder wall. Over the years, advancements in materials and coating technologies have led to the development of ceramic chrome piston rings, which...

The Impact of Chrome Coatings Being Phased Out Due to New REACH Regulations

The imminent phasing out of chrome coatings, driven by the stringent regulations outlined in the REACH framework, is sending ripples through industries that rely on these coatings for critical applications. From piston rings to bearings, valves to gearboxes, the...

Why Are Different Coatings Used For Piston Rings?

Piston rings have evolved in recent years. Until recently they were heavier, thicker, and made of cast iron. Modern rings are thinner, come in many widths, and must be precisely configured to suit the needs of the user. Coatings play an ever more important role when...

The Benefits of Vermicular Piston Rings

Piston rings are key components in the likes of marine and locomotive diesel combustion engines. The piston ring functions in an incredibly demanding environment, with high mechanical loads, high temperatures, and corrosive compounds all testing the strength and...

Why the right piston ring coating can extend longevity and lower costs

One significant factor in piston rings that often goes ignored is the specific material used on the outside of a piston ring. Whilst the lubricant used is often a major area of attention since it’s a significant factor in the amount of friction acting within the...

Which coating is right for my piston rings?

Choosing to coat your piston rings has been proven to extend their life and improve their efficiency. For example, coating a piston ring can prevent scuffing and reduce corrosion. If, however, you select the wrong coating for your piston rings you can cause excessive...

Piston Ring Maintenance

When Should I Replace My Pistons?

Piston rings are integral to the efficient running of a marine or industrial engine. If properly cared for, they can last a long time - significantly improving the lifespan of your machinery and saving time and money. Failure to regularly review your pistons - or...

Can overheating damage piston rings?

Even when the best precautions are taken, piston rings can still fail. Understanding why is integral to solve the problem. Overheating is one of the primary reasons piston rings fail. In this short guide, we’ll look at why this happens and what can be done to rectify...

What are the signs of worn piston rings?

Piston rings are a key engine component as they take care of several high workload functions at once. This, combined with the high temperature and corrosivity of their environment is one of the reasons that they go through a lot of wear and tear. An important part of...

3 Signs It’s Time To Change Your Piston Rings

Piston rings play an important role in both marine and industrial work. There is nothing more important than ensuring everything is running as it should be, which is why we are going to share with you our top 3 signs it’s time to change your piston rings. Too Much...

Summer maintenance checklist for your piston rings

Piston rings are a key part of any functioning vehicle body, whether it be marine piston rings for your boat or locomotive piston rings for your train. When you buy a piston ring, you expect assured quality and durability as it needs to perfectly seal the chamber of...

How should you store piston rings?

In order to protect the quality and longevity of piston rings, it is essential that they are stored correctly, in the right environment. Below we explore the correct conditions to store piston rings… Piston rings must always be stored horizontally If the rings are...

Company News & Industry Updates

Secondary treatment to cast iron rings available at Precision Products

Cast iron is an excellent material type for piston rings because it’s strong and durable. However, when it comes to piston and sealing rings, cast iron can benefit from a secondary treatment or coating to minimise the impact of wear and tear. Read on to discover the...

Precision Products 2021 Round-Up

While 2021 may have offered many challenges, we’re pleased to say that it’s also been a period of growth and success for us here at Precision Products UK. Agility, determination and great organisational teamwork have all been key contributors. Here’s our 2021...

MakeUK North East Yorkshire and Humberside Manufacturing Awards

Precision Products (UK) Ltd were proud to be recognised by the Make UK North East Yorkshire and Humberside Manufacturing Awards for their contribution to the sector in terms of business growth and strategy. Emerging from Brexit, economic uncertainty and the pandemic...